All forming operations deform sheet material by exposing it to

tension, compression, or both. Most part defects, such as splits and

wrinkles, occur in forming operations. Successful sheet metal forming

relies heavily on the metal's mechanical properties. The metal being

formed must have the ability to stretch and compress within given

limits. It also must be strong enough to satisfy the part's fit and

function. This balance between formability and strength often is hard

to achieve.

Most forming operations involve at least two basic

components: a punch, representing the male portion of the die, and the

cavity, representing the female portion.

Common Forming Die Types

Although many die types exist, this article focuses on those used in the most common forming operations.

Embossing Dies

Embossing

dies use tension to stretch metal into a shallow depression. The die

set primarily is composed of a punch and a cavity. The metal's

thickness and mechanical properties, along with the forming punch

geometry, determine the depth that can be achieved (see Figure 1).

|

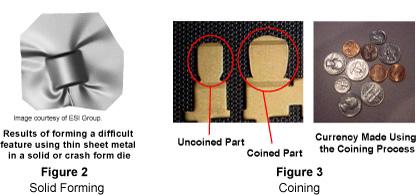

Solid Form/Dead Hit Dies

Solid

form/dead hit dies—also called crash forming dies—deform the metal

using only a punch and cavity. These dies do not control metal flow and

cannot prevent the metal from wrinkling or buckling. They are used to

form simple parts, such as brackets and braces, made from thick, stiff

metals that are more wrinkle-resistant than thinner metals. Because

this operation also uses tension to form the part, attempting to

solid-form difficult part geometries using thin metal often results in

severe failure (see Figure 2).

|

| Figure 4 Simple Bending |

Coining Dies

Coining

dies create the part's shape by squeezing the metal under extreme

pressure. Coining also can reduce the metal thickness. Coins (metal

currency) are created with the coining process. A simple round metal

slug is placed into the die and forced to flow into a given shape by

compressing it (see Figure 3).

Restrike Dies

The

restrike die operation fundamentally is a solid forming operation. The

main difference is that a restrike die is used after most of the major

forming already has been performed. The restrike die's function is to

finish forming features that could not be obtained in a previous

operation. Restrike dies add details such as sharp radii and small

embosses. They also help compensate for springback that occurred during

the initial forming.

|

| Figure 5 Bending |

A

restrike die operation often follows a drawing or trimming operation.

These dies, also referred to as qualifying dies, usually use tension to

re-form the part; however, compression also can be used.

Bending Dies

Bending

can be defined simply as a forming operation in which the metal is

deformed along a straight axis. Items such as tabs and channels are

created using the bending process. Achieving the correct bend angle in

a bending operation can be very difficult.

Among the various

bending methods are wipe bending, V bending, and rotary bending. All

three are very popular, and each has its advantages and disadvantages.

Both compression and tension occur during bending. Compression occurs

on the inside radius, while tension occurs on the outside radius. Figure 4 shows the compression and tension. Figure 5 shows the three basic bending types.

Flanging Dies

Flanging

is bending metal along a curved axis. Two basic types of flanges are

tension, or stretch, flanges, and compression, or shrink, flanges.

Tension flanges are susceptible to splitting, and shrink flanges are

susceptible to wrinkling.

|

| Figure 6 Flanging |

Flanges

are created using a flanging die that wipes the metal between a punch

and a lower die section. Both tension and compression occur during the

flanging process (see Figure 6).

Drawing Dies

Drawing

dies are the most impressive forming dies. Oil pans, automobile doors

and fenders, cookware, and door knobs are just a few parts manufactured

by drawing.

Draw dies create the part shape by controlling metal

flow into a cavity and over the forming punch. Draw dies utilize a

special pressure-loaded plate or ring called a draw pad or blank holder

to control the metal's flow into the cavity. This plate prevents the

metal from wrinkling as it flows into the cavity. Increasing or

decreasing the pressure exerted under the pad also controls how much

metal feeds into the die. Although compression can occur when the metal

is drawn, drawing uses mostly tension to obtain the part geometry (see Figure 7).

|

| Figure 7 Drawing |

Ironing Dies

Ironing

dies are similar to coining dies in that they deform the metal with

compression. However, unlike conventional coining, ironing squeezes

metal along a vertical wall. This highly compressive process unifies a

wall's thickness and increases the drawn vessel's length. Items such as

beverage and soup cans are made using an ironing process. Ironing

allows an aluminum can's wall thickness to be reduced to as little as

0.002 in. (see Figure 8).

|

Extruding Dies

In

extruding, the metal is flanged around the perimeter of a prepierced

hole. Like during stretch flanging, the metal is susceptible to

splitting during forming. Extrusions also are referred to as hole

expansions or continuous stretch flanges. Often extrusions are tapped

for holding fasteners used in the part assembly process (see Figure 9).

No comments:

Post a Comment